Tobacco Curing Methods

While tobacco is a necessity for pipe and cigar smoking, it's easy to overlook its preparation and how the leaf begins its journey. Tobacco is an extremely sensitive crop and the soil, climate, and curing process it's exposed to all play crucial roles in its production.

Once harvested, tobacco must undergo what is called a curing process, which prepares the leaves for further processing as curing allows for the naturally occurring excess moisture within tobacco to be drawn out. When raw and freshly picked, tobacco is typically green in color and because of its excessive moisture, it won't easily ignite or be smokable. Tobacco curing is sometimes referred to as color curing because as the tobacco undergoes the process, the color of the leaf will invariably change because its chlorophyll content is being altered, gradually becoming more yellow to brown in color.

The primary Tobacco curing methods consist of air curing, flue curing, sun curing, and fire curing. Each method has its own unique benefits and is used for different tobacco varietals, marking the first step in the manufacturing process of many of our cherished mixtures.

1. Air-Cured Tobacco

Air curing was among the first tobacco curing methods used; early settlers describe how Native Americans would dry tobacco leaves in the sun or in the shade of huts. Tobacco processing in the early colonies was primitive and evolved slowly over time. Initially, the leaves were simply picked and piled in heaps to dry but methods gradually advanced over time and it was discovered that tobacco cured better when hung.

Generally, air-cured tobacco is stalk-cut harvested and hung in well-ventilated barns for anywhere from three to twelve weeks and is complete when the leaf's central rib is free of moisture, resulting in leaves that are light tan to reddish-brown to deep brown in color.

As a natural curing process for tobacco, air curing generally takes the longest of all the methods. Air curing yields tobacco with low sugar content that will usually impart a mellow flavor and higher levels of nicotine. The most common types of air-cured tobacco are Burley and cigar leaf

2. Flue-Cured Tobacco

Flue curing refers to the type of barn used to cure tobacco and is a method that involves indirectly exposing the leaves to heat, created by transporting hot air, smoke, or steam through a pipe, or flue. That heat radiates throughout the enclosure, rapidly drying the tobacco and giving it a yellow color. At no point during flue curing is the tobacco directly exposed to any sort of fire or smoke like fire-cured tobacco. The entire process usually takes four to six days, after which the barn doors are opened to allow the leaves to absorb moisture from the air. Flue-cured tobacco will generally contain a higher sugar content compared to other curing methods, lower levels of nicotine, and impart a mild, slightly sweet flavor and aroma. Virginia tobaccos are the most commonly used varietal for flue curing.

3. Sun-Cured Tobacco

While some may consider sun-curing to be the same as air-curing, there is a slight difference between the two processes. Air-cured tobaccos are typically hung up in ventilated barns or shaded areas with the humidity closely monitored, while sun-cured tobaccos are spread out on racks and exposed to direct sunlight for a few days. This rapid drying method secures a bit of the natural sugar in the leaves, offering a slightly sweet taste when added to a blend.

Sun curing is predominantly used in the production of Oriental tobaccos grown in Asian and Mediterranean countries, regions where there is abundant sunlight and very little rain. Sun curing yields tobacco that is yellow to orange in color, has a high sugar content, and a lower level of nicotine. When sun-cured, the tobacco loses a significant amount of weight (sometimes up to 90%) due to the loss of moisture.

In terms of the flavor profile of sun-cured Oriental tobaccos, Sun-cured leaf tends to have a herbal, spicy character and Oriental tobaccos have a sweet and sour, somewhat nutty flavor, cashew, lemongrass, cardamom — those kinds of complex flavors.

A typical English blend will often combine Oriental tobacco with Virginia and Latakia, though the proportions of each component may vary. However, the various flavors of each component can play off each other in interesting ways depending on the quantity used, the curing process they were exposed to, and any topping or flavoring added later in the manufacturing process.

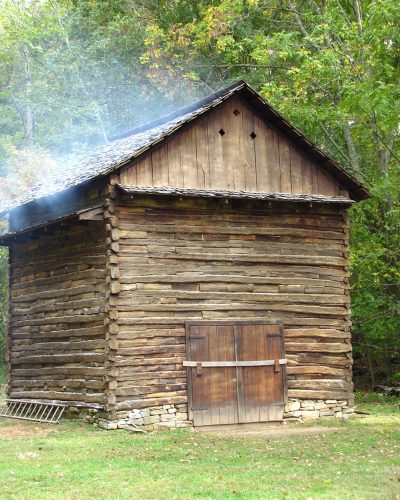

4. Fire-Cured Tobacco

The fire curing process can almost be viewed as barbecuing tobacco leaves, exposing the tobacco to a smoldering fire and imparting a distinctively smoky, woodsy flavor. Typically, fire-cured tobacco is hung in large barns similar to those used in air curing but are more tightly sealed to maximize the smoke exposure. Fires of hardwoods are kept on a continuous or intermittent low smolder and the process lasts anywhere between three days and ten weeks, depending on the tobacco and the desired results. Fire curing yields tobacco that is low in sugar, high in nicotine content, and adds a spicy kick to the flavor profile of the mixture it joins. Due to the amplified strength and flavor of dark fire-cured tobacco, it's often used sparingly in mixtures. "Typically, dark-fired isn't used in large quantities in a blend because it can be a pronounced and overpowering flavor, so it's often used as a condimental tobacco. Latakia is a notable example of fire-cured tobacco. It is often used as a condimental component in English/Balkan-style blends.

Royal Theodorus Niemeyer B.V. Holland. Blenders of Fine Pipe Tobaccos. A pipe in peace and quiet.

Jeffery Sitts. Tobacco Curing Methods. June 5, 2020. https://www.smokingpipes.com/smokingpipesblog/single.cfm/post/tobacco-curing-methods

Do you have pipe tobacco?

Yes, we have. Please contact our LINE ID: @vapourhouse